Molybdenum

Molybdenum alloys

This material could be used in a pure state (Mo) or in distinct types of alloys. Following we analize the properties and the advantages of each one of the Molybdenum alloys.

| Name | Elements | (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| W | Ti | Zr | C | La2O3 | Y2O3 | Hf | Cu | |

| Mo | ||||||||

| TZM | 0,4~0,55 | 0,06~0,12 | 0,01~0,04 | 0,08~0,14 | ||||

| MHC | 0,04~0,12 | |||||||

| ML | 0,2~3,0 | |||||||

| MY | 0,2~0,8 | |||||||

| MW | 20~50 | |||||||

| MCu | 0,3~30,0 |

1. Pure Molybdenum:

- High melting point and high elastic modulus.

- Low and resistor and vapor pressure.

- Good heat resistance, thermal conductivity and thermal expansion coefficient.

2. TZM Alloy (Titanio-Zirconio-Molibdeno)

Compared with pure molybdenum, TZM alloy has following advantages:

- Better heat resistance.

- Higher recrystallization temperature.

- Good creep resistance and weldability.

3. MHC Alloy (Molybdenum-Hafnium-Carbon)

MHC alloy has the following advantages which compared with TZM alloy :

- Better creep resistance;

- Higher heat resistance and recrystallization temperature.

4. MoLa Alloy (Molybdenum-Llanthanum)

MLa alloy compared with pure molybdenum has the following advantages:

- Better creep resistance and welding performance;

- Higher recrystallization temperature and higher thermal resistance.

- Good plasticity after high temperature use.

5. MY Alloy (Molybdenum-Yttrium)

MY alloy compared with pure molybdenum has the following advantages:

- Better oxidation resistance.

- Higher recrystallization temperature.

- Good weldability and molding.

- Good adhesion with melted glass.

6. MW Alloy (Molybdenum-Tungsten)

MW alloy compared to pure molybdenum alloy has the following advantages:

- Good resistance to molten metal corrosion interaction.

- Higher recrystallization temperature and hardness.

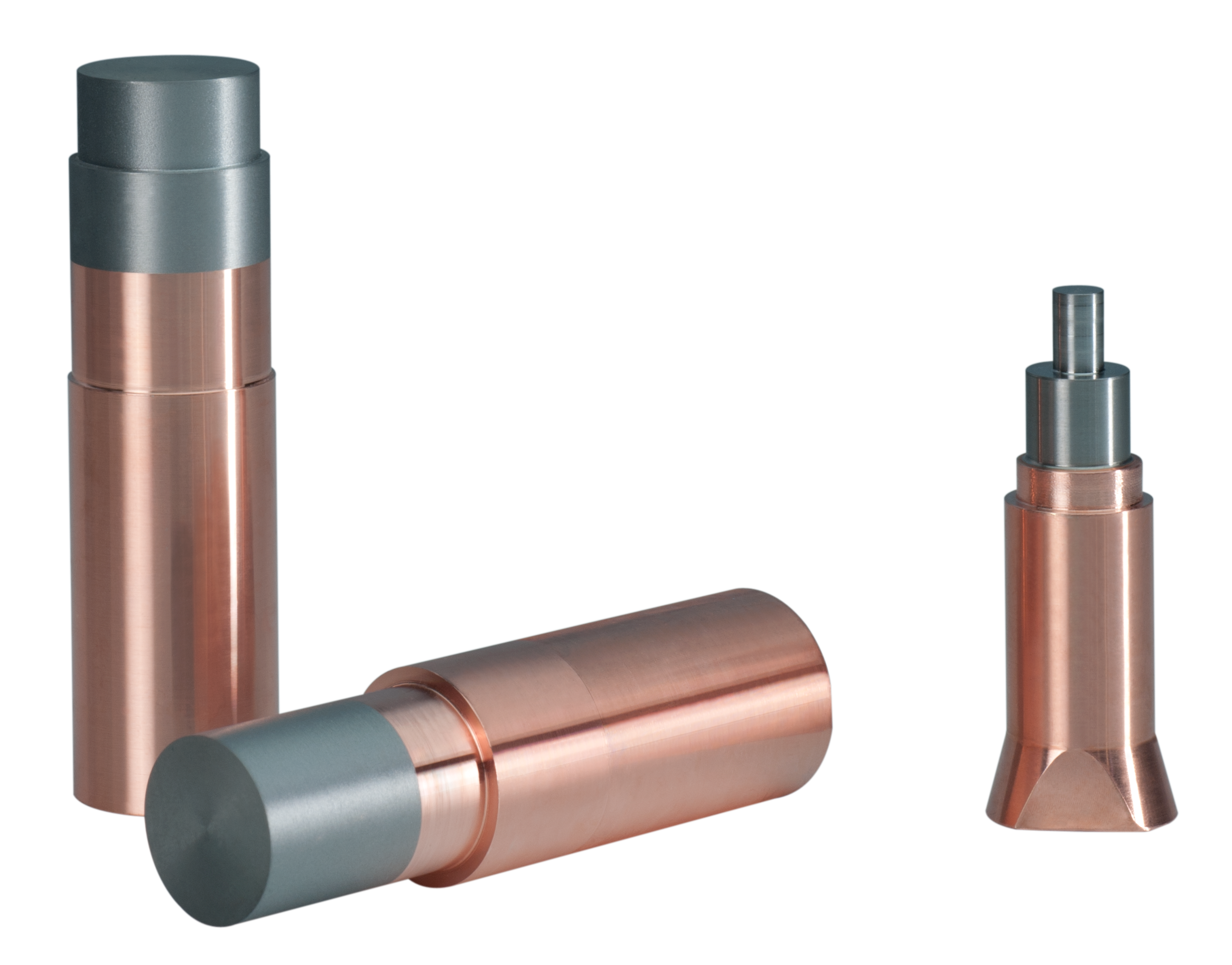

7. MCu Alloy (Molybdenum-Copper)

MCu alloy has the following advantages:

- Good thermal conductivity and thermal expansion.

Applications:

| Name | Nominal Composition | Applications |

|---|---|---|

| Pure Molybdenum | 99.95 Mo | Vacuum furnaces, glass melting, electronic devices, heat sink |

| TZM | 0.5Ti, O.08Z , 0.03C | Thermal processing tools, stoves installed appliances |

| MHC | 1~1.5Hf, 0.03~0.05C | Hot work tool |

| Mo-W | 10~30W | Molten zinc treatment, sputtering target |

| Mo-Re | 41 ~47.5 Re | Traveling wave tubes, rocket boosters |

| Mo-La | 0.5-1.5La (La203 state was near) | Sintering boat |

Find out more about applications of the molybdenum and its different alloys here.