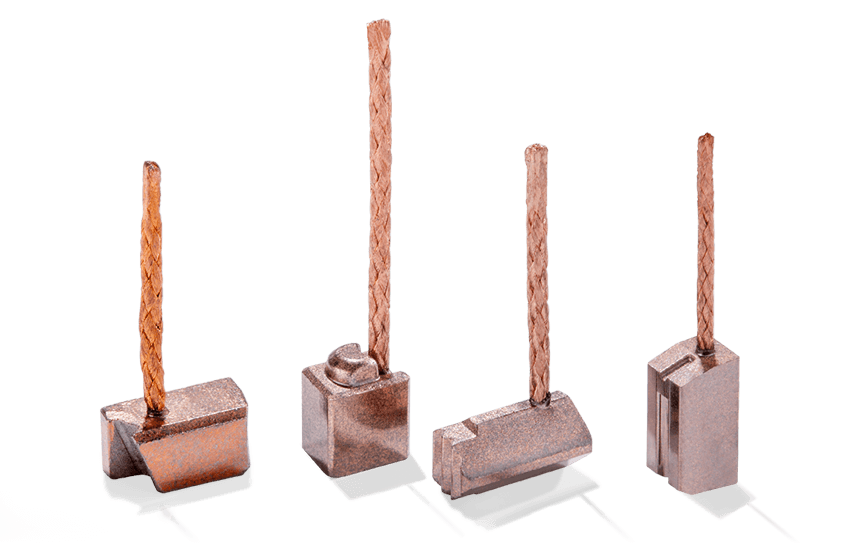

Carbon brushes for electric motors

Carbon brushes are one of the fundamental parts of a working electric motor. They can be defined as the element which makes the connection between the static part and the moving part inside an electric motor (rotor).

Brushes for electrical motors are elements which it´s intended use is to put the required pressure over the collectors or the rotatory rings, hence the contact can be made for the electrical current.

Types of Electric motor Brushes

There are, depending on the base material, different groups of electrical brushes:

- Amorphous carbon: Usually used in electro-portatil tools. Ideal for small motors with high speed revolutions.

- Electro-Graphite: Used in loading machines. Special material for continuous current motors and ringed alternate current motors, over 25Kw (20 H.p.) and intensities around 300/400 amps. When this intensities are crossed, we use the same materal but with different additives.

- Metal-Graphitic: Usually utilized in forklifts and cranes, as much in any motor subdued to very high intensities and low tension, because this kind of brush offers a very low electrical resistance and is able to support a very high electric charge.

- Baquelitics: Once upon a time, the most used of all materials. Nowadays more or less obsoletes in front of cheaper and/or lasting materials. They can support a high electricla charge during the starting time, as they have a very resistive brushes. Among their advantages, they can self-regulate the motor power but, in the other hand, they are very ductile.

- Flat brushes: Made with very compact materials, and specially destined to small spaces applications with a high level of conductivity, like dynamos or lightning rods. Ths is the only type pf brush were the composition can vary substantially form one application to another.

Common faults for carbon brushes

There is a wide variety of different faults with carbon brushes, following down there is a list with the most common:

- Quality: The wrong selection of the material for a carbo brush can short drastically the effective live of the brushes and even the lifespan of the motor, as it could be damaged by choosing a harder quality than needed.

- Dimensions: Once the brushes are worn out, their dimensions are completely altered, as usually happens with consumable parts. Thats why it is important to know beforehand the dimensions of a brand new brush.

- Springs: A heavy or less pressure upholding the brush to the motor can vary the lifespan of the brushes.

- Working temperature: A high working temperature (70º-120º) can alter the properties of the material, and even bend the brushes itself.

- Cable section: Even with a correct selection of the material and the right dimensions for the brushes, the wire which conduits the electricity needs to own enough section to manage the current in the system. This can lead to overheating and even rupture of the brushes.

- Other problems affecting the wire are a wrong insertion or a wrong terminal selection.

In case of doubt when choosing the material, its recommended to pick the softest one and increase the hardness gradually. Usually, harder grades can create sparks and damage the collector inside the motor.

Find some more information about Electric brushes here.