Graphite - Carbon-Graphite

Graphite (carbon-graphite) is, along with diamond or graphene, one of the allotropic forms in which carbon can occur. Black in color with a metallic sheen, graphite is very soft, opaque and easily exfoliated. It is made up exclusively of carbon atoms and at low temperatures it has little electrical conductivity, however, it behaves like a semiconductor at high temperatures. It is a material with refractory properties.

Graphite - Carbon-Graphite properties

– To work in dry/wet

– Low thermal expansion

– Corrosion resistance

– Low coefficient of friction

– Excellent thermal shock

– Self-lubricating

Properties | Isostatic | Resin | Antimony | |

|---|---|---|---|---|

| Density | g/cm3 | 1,85 | 1,80 | 2,40 |

| Porosity | % | 13 | 0,2 | 0,5 |

| Elastic Modulus | GPa | 11 | 20 | 25 |

| Compressive Strength | MPa | 98 | 200 | 220 |

| Flexural Strength | MPa | 49 | 80 | 90 |

| Thermal Expansion Coeff. | 10-6/ºC | 5,5 | 3,8 | 4,0 |

| Thermal Conductivity | W/mK | 116 | 10 | 15 |

| Working Temperature | ºC | 800 | 250 | 350 |

| These properties are typical average value | ||||

Graphite - Carbon-Graphite aplications

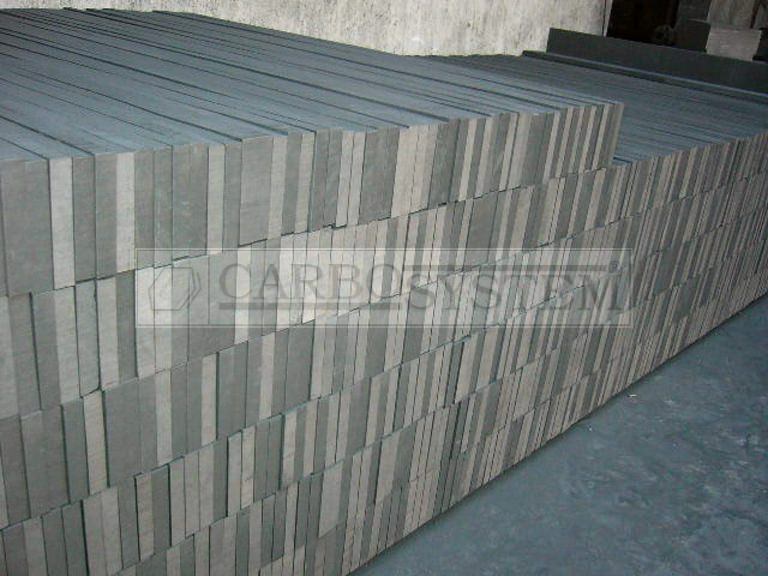

– Pieces, Plates, Tubes, Parts, etc. in Carbon-Graphite

– Crucibles, Dies, Molds, Rods, etc. in Carbon-Ggraphite

– Rings, Bearing, Seals, etc. in Carbon-Graphite

– Stacker Bar Inserts, Bottle Aligner, Take-out Inserts, etc. in Carbon-Graphite

– Electric Brushes, Strips, etc. in Carbon-Graphite

– Heating Elements, Furnace Parts, etc. in Carbon-Graphite

– Vanes, Blades, Vacuum Pumps Parts, etc. in Carbon-Graphite

Frequently asked questions about Graphite - Carbon-Graphite

What color is graphite?

Graphite has a dark gray color, with silver highlights. Depending on its composition, this gray hue may be more or less dark, approaching blacks.

What is the structure of the graphite?

Graphite in its most usual form has a flat hexagonal structure at the microstructural level. At the macrostructural level, it is ordered in the form of alternating layers composed of small groups of flat hexagons, which gives it one of its star properties, self-lubrication.

What type of mineral is graphite?

Graphite is a crystalline mineral, a form derived from coal. This crystalline orientation is the most stable that occurs naturally.

What kind of material is graphite?

Graphite is a ceramic material, composed of stacked carbon molecules. This structure is what gives it one of its most outstanding properties, self-lubrication.

What are the applications of graphite?

Graphite is a versatile material. Being an excellent driver, it has many electrical applications. If we observe its melting point in the absence of oxygen, close to 3000 ° C, it becomes an excellent material for casting or continuous casting molds. On the other hand, thanks to its non-stick, there are multiple applications in which it can be used as a pusher or slider, such as in the glass industry.

If you want to learn more about Graphite - Carbon-Graphite, you can check out our blog