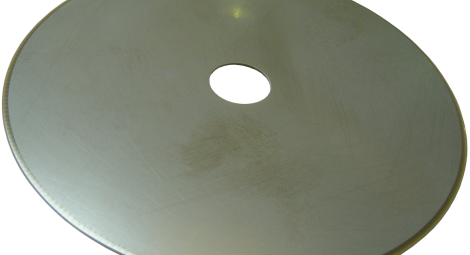

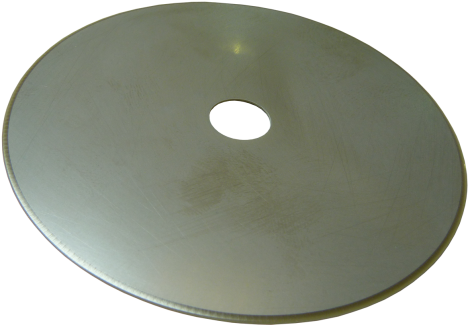

Circular blades

At Carbosystem, we constantly work to innovate in different sectors, one of the most active being the glass industry. In this sector, one of the most delicate applications that requires high precision in manufacturing, as well as the highest quality materials, are circular blades for marking glass ampoules.

This object, widely used in fields such as medicine, requires a manual opening system that does not endanger the operator. It is to meet this need that it is decided to mark micro channels cut in the neck of the same ampoule to facilitate its rupture.

To make this precise cut, circular blades made of tungsten carbide are used, which, turning at very high revolutions, manage to cut the surface of the glass without breaking it.

The measurements must be highly precise, both in the concentricity of the blade, even in its regular density, since otherwise, unbalances could occur in the revolutions, which could cause vibrations and these could damage the final product.

These blades are made entirely of tungsten carbide (or tungsten carbide) due to its hardness, but this material allows it to be worked in extreme conditions, such as high temperatures or environments with chemical loads that can become corrosive, and it is thanks to its resistance to corrosion, which greatly increases its durability.

At Carbosystem we manufacture this type of custom blades, meeting the highest quality standards, ensuring that each piece reaches its maximum useful life.