Degassing

With demand for non ferrous metal castings increasing in volume especially the castings of aluminium and aluminum alloy, there is also a growing pressure on foundries to improve casting quality as technical specifications for most industrial applications including building, engineering, transport, particularly aerospace and the automotive sector where its use has increased rapidly over the last few years. In order to remove impurities from the melt to provide cleaner, better quality metal, one of the most common and effective cleaning methods used by foundries is Rotary Degassing. With the increasing global tonnage and quality demand for aluminum castings, increasing globalization of the industry and increasing competition between foundries, foundries have to run the most efficient and cost effective processes possible in order to offer price competitive castings on a global scale.

Theoretical Principles

The impurities found in molten aluminium are of two main types: dissolved hydrogen and solid

non-metallic inclusions. The dissolved hydrogen comes out of solution as the metal cools and forms unwanted porosity. This porosity along with the non-metallic solid inclusions reduces the strength and adversely affects the final properties of castings produced from the aluminium.

In aluminium there is a reaction with water vapour as follows:

·2 Al + 3 H2 O = Al2 O3 + 3 H2

Molecular hydrogen then dissociates in the molten metal:

·3 H2 = 6 H

The molten aluminium also interacts with atmospheric oxygen thus in addition to the oxidation reaction seen in equation (a), the following reaction also occurs:

·4 Al + 3 O2 = 2 Al2 O3

Oxidation Resistance

This reaction results in oxide skin formation on the surface of the molten metal during the melting process and any subsequent transfer of the molten metal. The oxides produced become trapped in the bulk of the molten material, and are then transferred to the finished cast component. Further non-metallic inclusions such as carbides, nitrides or borides can come from sources such as the crucible material or other refractory materials.

Any inclusions produced will lead to defects in the structure of the casting and therefore will have a detrimental effect on mechanical properties, also they will lead to machining difficulties and possible damage to machine tools.

It is therefore essential to remove dissolved hydrogen and non-metallic inclusions from the molten metal prior to casting to achieve optimum quality. The treatment that has been developed to clean the metal is a physical process involving fluxing with an inert gas. The hydrogen, which is dissolved in the molten material, diffuses into the rising bubbles of fluxing gas and is transported to the surface of the molten material, this process is dependent on two major steps:

- Speed of diffusion of hydrogen through the diffusion boundary layer into the inert gas bubbles

- Concentration of hydrogen in the inert gas bubbles

Diffusion is the rate determining stage in degassing, therefore, the following requirements are necessary for optimum degassing efficiency:

- Small size of the inert gas bubbles with long dwell time in the molten metal. This ensures a large surface contact area between the inert gas bubble and the molten metal and therefore a higher coefficient of mass transfer with regard to the diffusion layer

- Consistently broad distribution of inert gas bubbles over the entire cross-section of the molten metal

- Adequate motion of molten material which accelerates the transport of hydrogen to the inert gas bubble

- A quiescent surface of the molten material bath in order to avoid fresh absorption of hydrogen from reaction with the atmosphere.

Oxides and other non-metallic inclusions are mainly removed by flotation as the small inert gas bubbles attach themselves to the oxides and float them to the surface of the bath. The principles that apply to hydrogen removal also apply to the removal of oxides.

Molten Metal Purification

Aluminium foundries have long been aware of the need for an effective fluxing gas treatment to remove hydrogen and inclusions. So recent development has been to fulfill this requirement and achieve the best possible degassing efficiency. The major breakthrough in automated, efficient, cost effective degassing came with the developments of rotary degassing. The principle of these machines need rotor can generates very fine bubbles of inert gases that are evenly and consistently distributed throughout the metal bath.

The rotary degassing technique removes these undesirable components by bubbling a gas, normally nitrogen, through the molten metal. This gas is normally introduced by means of a degassing rotor, which reduces the bubble size and disperses the nitrogen throughout the molten metal bath. As the resulting gas bubbles rise through the mass of molten metal they absorb the hydrogen dissolved in the metal and remove it from the melt. In addition, the non metallic solid particles are swept up to the surface by the flotation effect created by the bubbles and can then be removed by skimming off the metal. To meet these requirements of foundries, Carbosystem designs and manufactures full range of graphite tools to meet the requirements of refiners and foundry men for inert gases or active gases de-gassing.

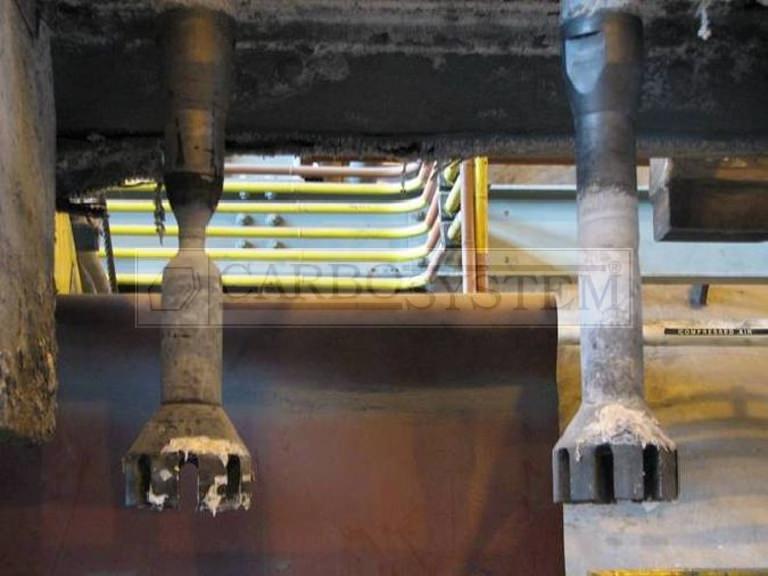

Carbosystem Graphite Rotors and Shafts have proved successful in numerously foundries worldwide.

Performance Graphite Rotors and Shafts

Although several material systems are available commercially for degassing rotors, the industry is dominated by machined graphite, in a two part assembly format, incorporating a separate shaft and rotor head. However, conventional graphite rotors easily degrade during use as the shaft and rotor head erode.

As the rotor head geometry degrades the efficiency of hydrogen removal reduces with time. Eventually the rotor head efficiency is reduced and the shaft thins to a point that breaking occurs and the rotor assembly has to be replaced. Given this failure mechanism, improved efficiency of the rotary degassing process should be achieved through improved material and rotor head design to increase the service life and maintain performance of the rotors compared to those currently available to foundries.

Carbosystem was prompted to improve the normal oxidation resistant impregnated graphite to achieve higher quality castings. Intensive investigations with the existing rotor, combined with theoretical studies, simulations, extensive modeling and practical tests have culminated in the development of our new high performance rotor. Finally, Carbosystem use a unique Oxidation Resistance treated method for the graphite rotors and shafts which significantly increase the oxidation and erosion resistance of the rotors and shafts and on optimizing the rotors and shafts design to achieve better distribution of the nitrogen gas into the melt in the degassing process.

Based on the Broad Carbon Graphite Technologies and the Continually Increasing Know-how, Carbosystem offers Graphite Rotors and Shafts with an outstanding level of quality and the highest degree of reliability to meet the requirements of refiners and foundrymen for inert gases or active gases de-gassing which can improve the cost effectiveness of the rotary degassing process by engineering a longer life rotary degassing consumable coupled with improved degassing efficiency.

Case Studies

Carbosystem’s Graphite Rotors and shafts have been compared with the conventional rotors and shafts in numerous foundries from their actual works of aluminium refining and casting. Carbosystem’s unique anti-oxidation treatment Graphite Rotors and Shafts have been proved to last an estimated 5 times longer than that of the conventional anti-oxidation treatment graphite rotors and shafts.

Compared with the industry standard impregnated graphite rotors which currently dominate this application, the erosion of Carbosystem graphite rotors and shafts was considerably reduced and the rotors and shafts also displayed a more non-wetting surface, making it much easier to keep clean.

Carbosystem’s high performance rotors and shafts with unique oxidation resistance treatment can provide foundries with a far longer service life, both in terms of durability and degassing efficiency

Graphite Degassing Components

Carbosystem manufactures full range of graphite degassing components for metal processing. All below graphite components are available with oxidation resistant treatment for extended products service life.

- Flow tubes

- Graphite rotors and shafts

- Special rotors for degassing

Applications and Industry

Carbosystem’s graphite degassing component is a best choice for purifying and degassing of molten metal in the following industries:

- Aluminum and aluminium alloys manufacturing

- Zinc and Zinc alloys manufacturing

- Magnesium and copper manufacturing

- Precious metals and their alloys manufacturing, etc.

Carbosystem Advantages to offer Graphite Degassing Components

- Unique oxidation resistant

- Custom parts available

- Extensive CNC machining capability

- Low permeability

- Broad industry experience

- Many years of graphite manufacturing